B7150SE / B9100SE Back-Up Tip Set - Short

Home / Product

/

- B7150SE / B9100SE Back-Up Tip Set - Short

Home / Product

/

B90394060A

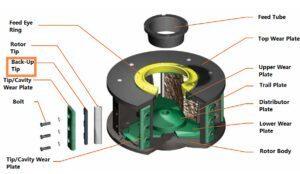

Back-Up Tips are one of the most frequently replaced and most worn wear parts in VSI crushers.

Rettek applies its unique welding technology to the combination of Back-Up Tips and carbide to produce high-quality welded Back-Up Tips that are widely used around the world.

Welded Back-Up Tips have higher strength than traditional bonded Back-Up Tips and can better cope with the high-impact, highly corrosive, high-speed and high-heat working environment generated when the VSI crusher is working.

It solves most of the problems of cemented carbide breaking or even falling off during the work process, helping users save maintenance and downtime costs of VSI equipment.

Our welding Back-Up Tips produced help users increase their original service life time.

This is our most popular product category and the product for which we have the most production experience.

Now, after more than ten years of development of carbide tools, we have become the largest manufacturer of carbide welding throw heads in China, and our achievements in the field of crushing tools are particularly outstanding.

Crushing tool accessories have always been in great market demand domestically and even overseas as consumable products for domestic sand making, mining wood chips, and agricultural crushing. The quality of the accessories themselves is the most concerning to users.

As a leader in cutting-edge crushing tool accessories in China, Rettek has been engaged in research and production in the crushing field for many years. It brings its experience and achievements to crushing tool accessories and controls the quality and cost of the tools from all aspects.

To this day, Rettek has developed a series of crushing models that are recognized for both quality and reputation in the domestic high-end crushing market.

And we continue to develop new products with properties such as wear resistance, corrosion resistance, impact resistance and high strength. We are committed to reducing crushing costs and improving crushing efficiency while customizing the wear-resistant parts they need for all our customers and actively solving problems.

We will continue to move forward on this road and bring our own strength to the crushing industry.

Zigong Rettek New Materials Co., Ltd. is a factory-type enterprise that independently develops and produces tools. We have a complete production line of carbide tools.

From the production, batching, pressing and vacuum sintering of alloy raw materials; to the design, production and welding of tools, every specific production process is integrated and managed internally by Rettek, starting from every detail of production and integrating production costs Combined with product quality control, we are committed to creating crushing products that satisfy customers.

No 146, Group 5, Dongjiacun, Xinmin town, Daan district, Zigong City, Sichuan Province

Monday to Sunday 8:30 - 17:00